Training for Module MTM Universal Analysis System (UAS) – MTM Analysis

EU-Projekt TRINITY

Hello!

My name is Edwin Lotter. I’m CEO of LP-Montagetechnik, a German Company which plans, develops and implements manual and semi-automated assembly workstations respectively assembly lines, such as one-piece flow systems and so on.

In this article + video I will explain some basic information about MTM analysis in general, its origin and the main advantages in using this method.

MTM (Methods Time Measurement) is a procedure for analysing work processes and determining planned times.

MTM is ideal to create work processes to achieve high benefit and to eliminate waste already in the planning phase. Furthermore, the use of MTM helps to design workplaces more ergonomically to ensure that work does not make the worker sick – and of course, this is an important aspect and one of the main approaches.

MTM finds its justification especially in the planning processes. To create an analysis it is only necessary to have an idea of the planned work process and the structure of the work systems which will be used.

In contrast to the time recording by means of a stopwatch (like for example REFA technicians do), it is not necessary to find an existing process or workplace for the application of the MTM method. Therefore MTM is an appropriate tool to calculate working times before the before the equipment is available.

The use of MTM works, because all movements made by the human are attributed to certain basic movements for which the time is known.

Origin of MTM Analysis

Three American ergonomists, Mr. Maynard, Mr. Schwab and Mr. Stegemerten had a consulting contract from Westinghouse Electric Corp and developed the basic data process of the MTM between 1940 and 1948. In the 1960s, MTM was expanded and modified to the systems we use today.

The current medium at that time was 16mm film (no computers or such modern things were available). The idea for the development of MTM was therefore to record all manual activities that humans can carry out several times and thereby obtain average values derived from the recorded time values.

The medium of 16 mm film creates 100.000 pictures per hour. This means that one picture is the time equivalent of 1 part of 100.000 parts in one hour.

On this list on the right you can see that the smallest time unit is 1 TMU (Time Measurement Unit) and if you convert that, you get 27.8 TMU per one second.

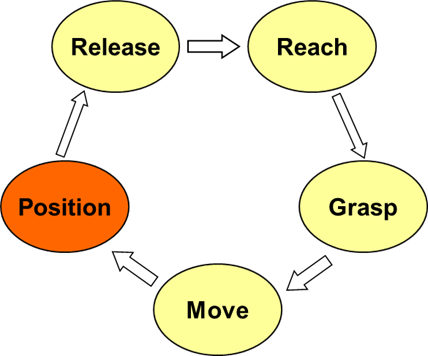

This picture shows the MTM control loop which contains the five basic movements of MTM.

Reach (to a part or tool) – grasp (this part or tool) – move (back) – positioning for example of a part – and release.

These basic motion elements are supplemented by additional elements like walking, bend over and straighten up, visual control, handling tools and so on.

The main advantages of MTM are:

- applicable in every branch of the economy

- generally understandable

- can be learned without special prior knowledge

- internationally identical handling

- execution time is self-evident with the given method

Due to the worldwide uniform coding of the movement elements, MTM is valid worldwide and is understood by all trained employees. The time determined by MTM corresponds to that which a person skilled in the art can achieve over a whole working day.

Caution:

Mental work and process times such as screwing times, soldering processes etc. are not detectable by MTM codes. These things have to be estimated or measured and added to the MTM calculation sheet as a PT (Process Time).

The results of MTM analysis are particularly useful for

- planning future operations

- calculations

- change management

- optimisation

- visualisation of current process state (primary and secondary analysis).

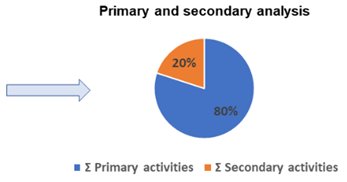

Primary and secondary effort means the distinction of effort which brings a value in terms of customers benefit (these are the primary ones) and secondary effort, which brings no benefit. The challenge is to minimize the secondary as much as possible to strengthen the primary effort.

The following preconditions are decisive for the determined time and its reproducibility:

- Average talented person (not the fastest and not the slowest of the district)

- Good practice in handling (the worker should not do it for the first time, he or she should be trained)

- Appropriate parts (parts should fit without for example damages or dimensional deviations etc.)

However, it is important that the operator is trained in MTM as there are many rules to be observed when using MTM.

MTM Universal Analysis System (UAS)

Several MTM analysis systems, like MTM-1, MTM-SD and some more are listed under the MTM brand.

In practice, MTM UAS is mostly used because this system combines certain basic movements into compound motion types. This considerably shortens the analysis time with almost the same accuracy in comparison to MTM 1 (basic method).

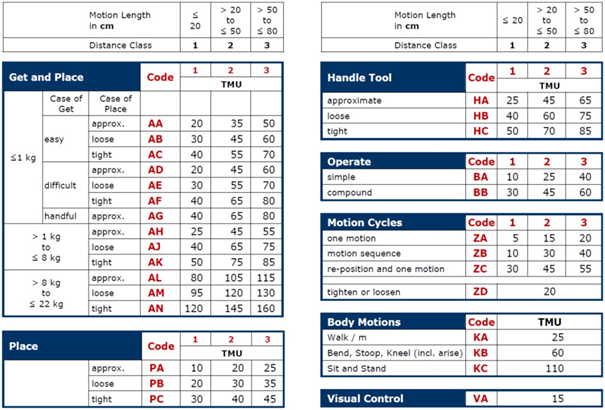

The MTM UAS code card is shown here and as can be seen the card is divided in several zones with columns and lines for different types of movements, handlings, distances a.s.o.

What formats and standards can be used for the MTM calculation? Several methods are available, such as:

- MTM time block tables (to fill in and calculate manually, based on the code card) – a sheet of paper, a pencil, and a pocket calculator

- Computer-aided procedures like TiCon4 (available at the MTM association – for costs ask MTM association)

- MTM-UAS calculation sheet including primary and secondary analysis1), developed by LP-Montagetechnik GmbH, based on an Excel calculation sheet (available at LP – for costs ask LP-Montagetechnik)

The primary-secondary analysis differentiates between value-adding (primary) and non-value-adding (secondary) effort. The key figure generated from this is a measure of the efficiency of a work system (P-S-A was developed by Prof. Bruno Lotter in 1979 based on MTM knowledge and became part of industrial engineering in Germany).

The next article + video (currently under construction) explains the use of MTM UAS in a real application in which the work content of assembling components in a circuit board is allocated between humans and robots.

Learn more about TRINITY Project: http://www.trinityrobotics.eu

This project has received funding from the Eropean Union’s Horizon 2020 research and innivation programme under grant agreement No 825196

Direkte Beratung vom Inhaber persönlich

Jetzt unverbindlich anfragen

Edwin Lotter ist die Koryphäe rund um die Montagetechnik und ein international gefragter Spezialist.

Sein Vater Prof. Bruno Lotter galt als der Montage-Papst

Unzählige Publikationen und zahlreiche Fachbücher zeugen von der Erfahrung und dem Know-how im Haus LP Montagetechnik. Hier erhalten Sie einen kleinen Einblick: Bücher, Artikel

Profitieren Sie von unserem Wissen und senden Sie uns eine Anfrage. Wir unterstützen Sie schnell und gerne.

Chefberatung

Höchste Beratungsqualität

Umfassend und individuell